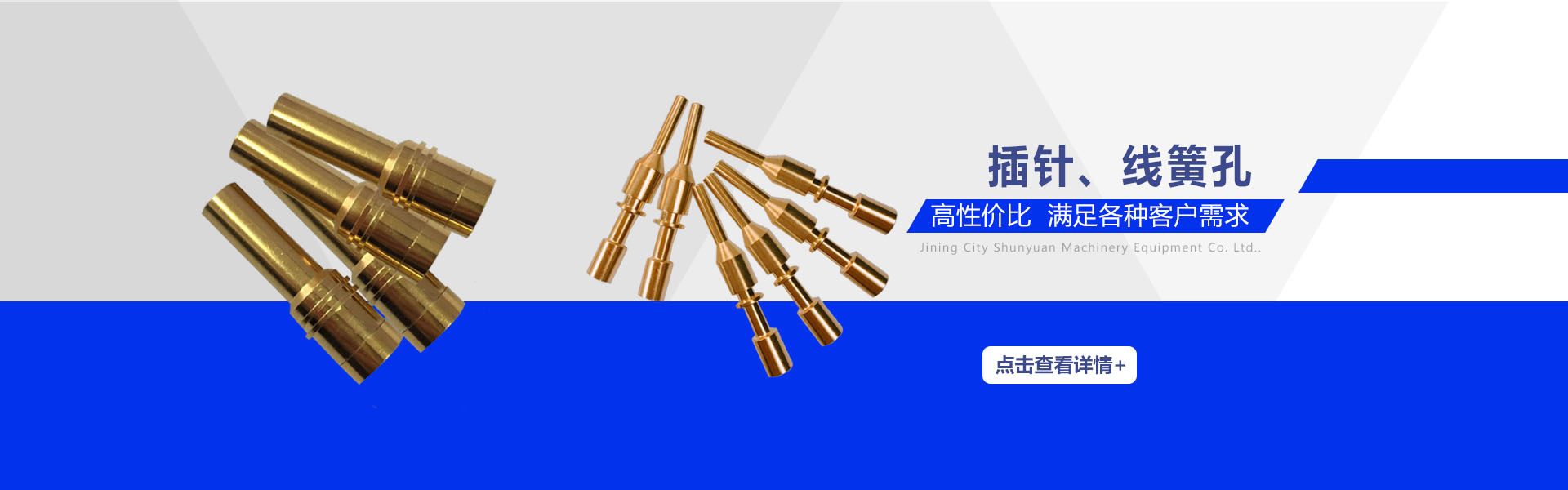

线簧插孔介绍Introduction of Wire Spring Socket

2024-07-26 来自: 华海电器 浏览次数:

线簧插孔,全称为单叶回转双曲面线簧插孔,是电连接器(即接插件)产品上使用的一种高可靠插孔组件。其孔内由多根弹性镀金或镀银金属丝按单叶回转双曲面的直母线排列,并与内套直母线形成一夹角。当插针插入线簧孔时,线簧丝在径向和轴向都会发生弹性变形,插针即与线簧孔中多根独立的线簧丝同时接触,构成多个独立的电流通路。

线簧插孔具有以下突出优点:

接触电阻低而稳定:当航空插座插入时,这些弹性金属丝会紧紧地包围在插座周围,产生多线接触,一对针眼可以作为几对一般针、孔并联使用。

插拔力小:插拔过程较为柔和。

接触件磨损低:能减少接触部位的磨损。

插拔寿命长:插拔次数可达5000次以上。

可靠性高:在强力振动冲击环境中,能保持电接触的高可靠性(瞬断时间小于1μs)。

由于具备上述优良性能,线簧插孔主要用于各种关键设备用连接器,如航空航天、武器装备、医疗设备、汽车电子测试、铁路机车车辆、电子通讯、智能设备、石油、化工、勘探等领域。

根据不同的需求和应用场景,线簧插孔可能会有一些特殊的设计和改进。例如密绕双曲面线簧插孔,它采用特殊的装配方法把几十根乃至上百根高弹性线簧丝沿基体孔内壁一根挨一根密绕而成,具有极低的接触电阻、体积小、插拔力柔和、抗震动、耐冲击、插拔寿命长等特点,且在高震动、耐冲击场合其瞬断时间小于1μs,在信号保真和大电流传输方面表现出色,可替代传统的双曲面线簧插孔,在军工连接器、电源连接器、高可靠控制连接器等方面逐步推广使用。

另外,还有无内套线簧孔,它相对于一些现有技术中的无内套线簧孔,不需要再设置过渡芯轴,可相对缩短整个线簧孔的轴向长度,利于产品的高精密集成化发展。其包括前护套、线簧丝和端接后套。线簧丝形成双曲面结构,前端与前护套前端固定连接;端接后套前端沿周向分布有多个限位槽,其前端插接装配在前护套中,线簧丝一一对应地定位插装在限位槽中,在两者相对转动设定角度并固定装配在一起时,线簧丝的前端和后端周向错位而形成双曲面结构,后端设置用于连接到对应线路的端接结构。

在实际应用中,选择线簧插孔时,需要考虑具体的设备要求、工作环境、电流负载等因素,以确保其能够满足特定的连接需求和可靠性要求。

Introduction of Wire Spring Socket

Spring-Loaded Connectors, officially known as Single-Leaf Rotational Hyperboloid Spring-Loaded Connectors, are a type of high-reliability socket component used in electrical connectors (i.e., plug-and-socket products). The socket contains multiple elastic metal wires, either gold-plated or silver-plated, arranged in a single-leaf rotational hyperboloid along the principal axis, forming an angle with the inner sleeve’s principal axis. When a pin is inserted into the spring-loaded socket, the spring wires undergo elastic deformation both radially and axially, allowing the pin to make contact with multiple independent spring wires simultaneously.

Advantages of Spring-Loaded Connectors include:

· Low and Stable Contact Resistance: When an aviation plug is inserted, the elastic metal wires tightly encircle the plug, creating multiple line contacts. A pair of pins can be used as several pairs of standard pins and sockets in parallel.

· Low Insertion/Removal Force: The insertion and removal process is relatively smooth.

· Low Wear on Contacts: This reduces wear on the contact points.

· Long Insertion/Removal Life: The connector can withstand more than 5000 insertion/removal cycles.

· High Reliability: It maintains high electrical contact reliability even in strong vibration and shock environments (with a break time of less than 1μs).

Due to these excellent properties, spring-loaded connectors are primarily used in critical equipment connectors, such as in aerospace, weaponry, medical devices, automotive electronics testing, railway locomotives and vehicles, electronic communications, smart devices, oil and chemical industries, exploration, and other fields.

Special Designs and Improvements may be found based on different needs and application scenarios. For example:

· Tightly Wound Hyperboloid Spring-Loaded Connectors: These use a special assembly method where dozens to hundreds of high-elasticity spring wires are wound tightly along the inner wall of the base hole. They feature extremely low contact resistance, compact size, smooth insertion/removal force, vibration resistance, shock resistance, and long insertion/removal life. In high-vibration and shock-resistant applications, their break time is less than 1μs, demonstrating excellent signal fidelity and high current transmission, making them a viable alternative to traditional hyperboloid spring-loaded connectors. They are gradually being promoted in military connectors, power connectors, and high-reliability control connectors.

· Non-Inner-Sleeve Spring-Loaded Connectors: Unlike some existing technologies, these do not require an intermediate core shaft, which can shorten the axial length of the entire spring-loaded connector, facilitating the development of highly precise and integrated products. This type includes a front sleeve, spring wires, and an end-terminals sleeve. The spring wires form a hyperboloid structure, with the front end fixed to the front sleeve. The end-terminals sleeve has multiple limiting slots distributed around the circumference at its front end. This sleeve is assembled into the front sleeve, and the spring wires are positioned in the limiting slots. When the two components are rotated to a set angle and fixed together, the front and rear ends of the spring wires are circumferentially displaced to form a hyperboloid structure. The rear end is designed for connection to the corresponding circuit.

In practical applications, when selecting a spring-loaded connector, it is necessary to consider specific equipment requirements, working environment, and current load to ensure that it meets the specific connection and reliability requirements.